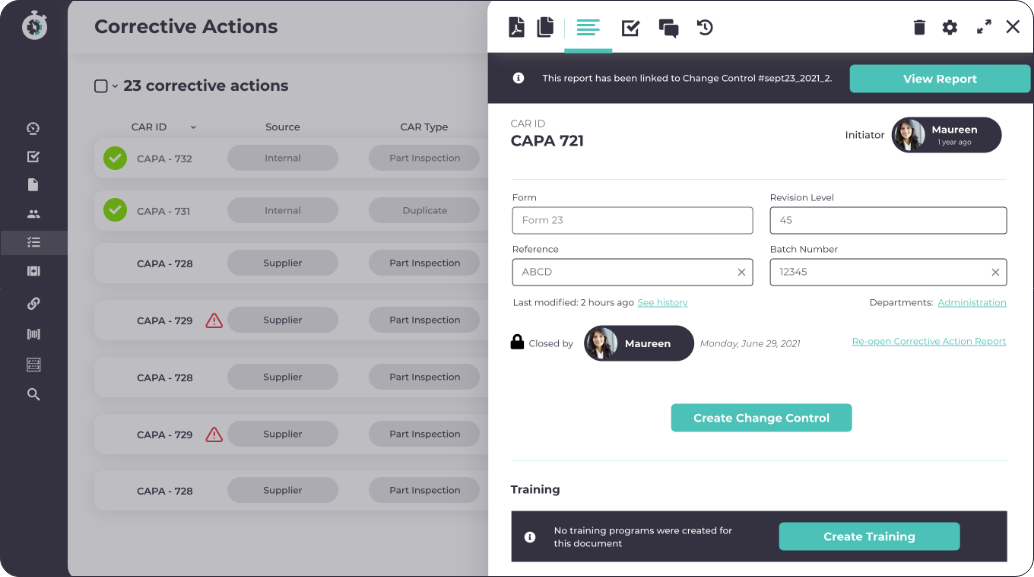

CAPA reports (corrective and preventative action reports) are at the center of any quality management system. We have built a CAPA software module into Isolocity’s quality management software in order to make this process more seamless for the user.

The CAPA module includes: CAPA, Deviations, Non Conformances, Out of specification and Customer complaints.